CXSD6289该设备需要12伏和5伏电源。如果电源不可用,设备可提供可选的并联调节器

5V电源为5.8V。两个输出都有独立的软启动和启用SS/EN管脚上组合的功能。从每个

SS/EN插脚接地,设置软启动时间,拉动SS/EN引脚电压低于1V以禁用调节器。该装置还提供180°相位在OUT1和OUT2之间切换功能。

-

[ 产品资料下载 ]

目录

1.产品概述 2.产品特点

3.应用范围 4.下载产品资料PDF文档

5.产品封装图 6.电路原理图

7.功能概述 8.相关产品

一,产品概述(General Description)

The CXSD6289 has two synchronous buck PWM control-lers with high

precision internal references voltage to of-fer accurate outputs. The PWM

controllers are designed to drive two N-channel MOSFETs in synchronous

buck topology. The device requires 12V and 5V power supplies.If the 5V

supply is not available, the device can offer an optional shunt regulator

5.8V for 5V supply.Both outputs have independent soft-start and enable

func-tions combined on the SS/EN pin. Connecting a capaci-tor from each

SS/EN pin to the ground for setting the soft-start time, and pulling the SS/EN

pin voltage below 1V to disable regulator. The device also offers 180°phase

shift function between OUT1 and OUT2.The default switching frequency is

300kHz (keep the FS pin open or short to GND), and the device also provides

the programmable switching frequency function to ad-just the switching frequency

from 70kHz to 800kHz. Con-necting a resistor from FS pin to GND increases the

switching frequency. Conversely, connecting a resistor from FS pin to VCC12

decreases the switching frequency.There is no current sensing or under-voltage

sensing on the CXSD6289. However, it provides a simple short-circuit protection by monitoring the COMP1 pin and COMP2 pin for over-voltage. When any of two pins

exceed their trip point and the condition keeps for 1-2 internal clock cycles (3-6us at

300kHz), all regulators are latched off.

二.产品特点(Features)

1.)Two Synchronous Buck Converters(OUT1,OUT2)

2.)Converter Input Voltage Range up to 12V

3.)0.6V Reference for OUT1 with 0.8% Accuracy

4.)3.3V Reference for OUT2 with 0.8% Accuracy

5.)Both Outputs have Independent Soft-Start and

Enable Functions

6.)Internal 300kHz Oscillator and Programmable

Frequency Range from 70 kHz to 800kHz

7.)180 Degrees Phase Shift etween OUT1 and OUT2

8.)Short-Circuit Protection

9.)Thermally Enhanced SOP-20 Package

10.)Lead Free and Green Devices Available

(RoHS Compliant)

三,应用范围 (Applications)

Graphic Cards

Low-Voltage Distributed Power Supplies

SMPS Application

四.下载产品资料PDF文档

需要详细的PDF规格书请扫一扫微信联系我们,还可以获得免费样品以及技术支持!

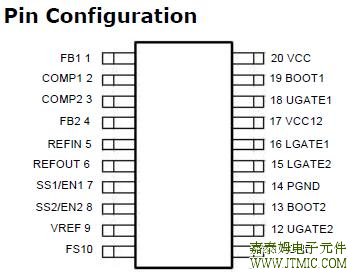

五,产品封装图 (Package)

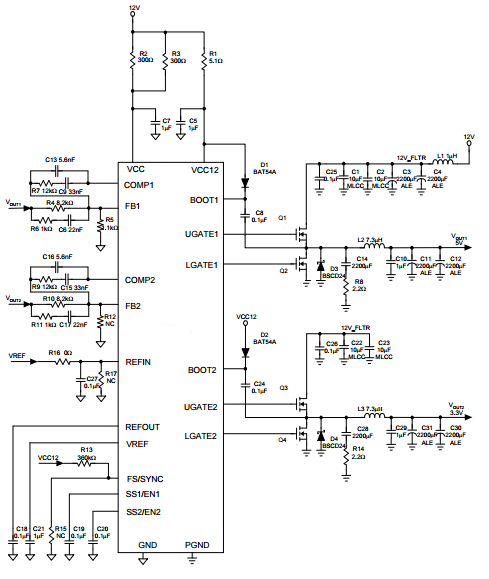

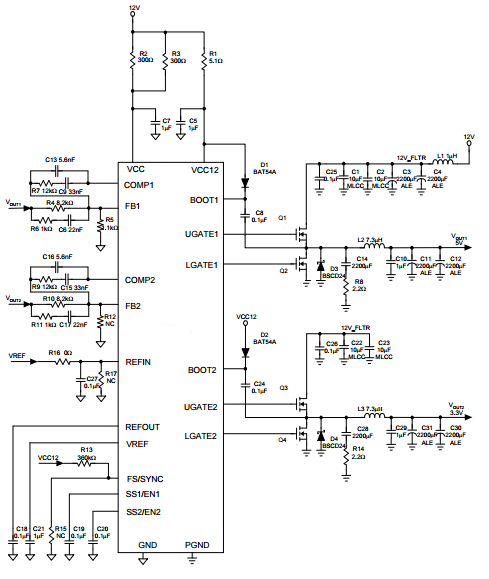

六.电路原理图

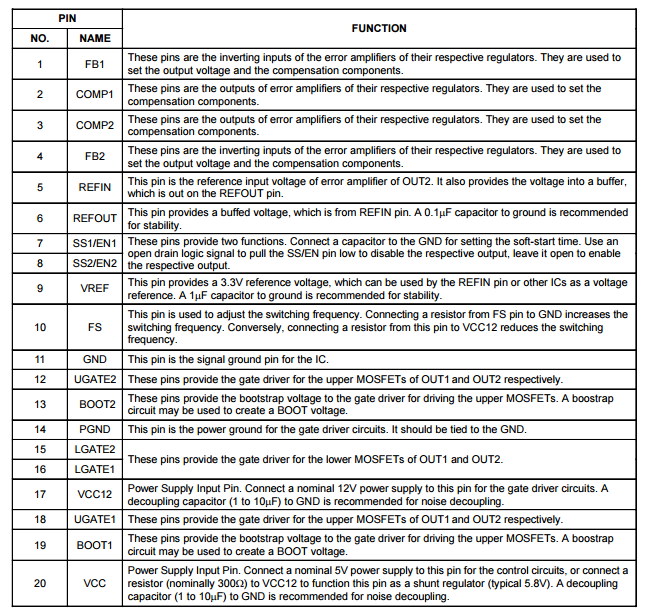

七,功能概述

Output Inductor Selection (Cont.)

Where Fs is the switching frequency of the regulator. Al-though increase the inductor value and frequency

reduce the ripple current and voltage, but there is a tradeoff ex-ists between the inductor’s ripple current and

the regula-tor load transient response time.A smaller inductor will give the regulator a faster load transient

response at the expense of higher ripple current.Increasing the switching frequency (FS) also reduces the

ripple current and voltage, but it will increase the switch-ing loss of the MOSFET and the power dissipation

of the converter. The maximum ripple current occurs at the maximum input voltage. A good starting point is

to choose the ripple current to be approximately 30% of the maxi-mum output current.Once the inductance

value has been chosen, select an inductor that is capable of carrying the required peak cur-rent without going

into saturation. In some types of inductors, especially core that is made of ferrite, the ripple current will increase

abruptly when it saturates. This will result in a larger output ripple voltage.

Output Capacitor Selection

Higher Capacitor value and lower ESR reduce the output ripple and the load transient drop. Therefore select high

performance low ESR capacitors that are intended for switching regulator applications. In some applications,

multiple capacitors have to be parallel to achieve the de-sired ESR value. A small decoupling capacitor in parallel

for bypassing the noise is also recommended, and the voltage rating of the output capacitors are also must be

considered. If tantalum capacitors are used, make sure they are surge tested by the manufactures. If in doubt,

consult the capacitors manufacturer.

Input Capacitor Selection

The input capacitor is chosen based on the voltage rating and the RMS current rating. For reliable operation,

select the capacitor voltage rating to be at least 1.3 times higher than the maximum input voltage.

The maximum RMS current rating requirement is approxi-mately IOUT/2, where IOUT is the load current.

During power up, the input capacitors have to handle large amount of surge current. If tantalum capacitors

are used, make sure they are surge tested by the manufactures. If in doubt, consult the capacitors

manufacturer. For high frequency decoupling, a ceramic capacitor 1uF can be connected between the

drain of upper MOSFET and the source of lower MOSFET.

MOSFET Selection

The selection of the N-channel power MOSFETs are de-termined by the RDS(ON), reverse transfer

capacitance (CRSS) and maximum output current requirement. The losses in the MOSFETs have

two components: conduction loss and transition loss. For the upper and lower MOSFET, the

losses are approximately given by the following :

PUPPER=IOUT(1+TC)(RDS(ON))D+(0.5)(IOUT)(VIN)(tSW)FS

PLOWER=IOUT(1+TC)(RDS(ON))(1-D)

Where I is the load current OUT TC is the temperature dependency of RDS(ON) F is the switching

frequency St is the switching interval sw D is the duty cycle Note that both MOSFETs have

conduction losses while the upper MOSFET include an additional transition loss.The switching

internal, tsw, is a function of the reverse transfer capacitance CRSS. The (1+TC) term is to

factor in the temperature depen-dency of the RDS(ON) and can be extracted from the “RDS(ON)

vs Temperature” curve of the power MOSFET.

Short Circuit Protection

The CXSD6289 provides a simple short circuit protection function, and it is not easy to predict its

performance, since many factors can affect how well it works. Therefore, the limitations and

suggestions of this method must be pro-vided for users to understand how to work it well.The

short circuit protection was not designed to work for the output in initial short condition. In this

case, the short circuit protection may not work, and damage the MOSFETs. If the circuit still works,

remove the short can cause an inductive kick on the phase pin, and it may damage the IC and

MOSFETs. If the resistance of the short is not low enough to cause protection, the regulator will

work as the load has

Short Circuit Protection (Cont.)

increased, and continue to regulate up until the MOSFETs is damaged. The resistance of the short

should include wiring, PCB traces, contact resistances, and all of the return paths.The higher duty

cycle will give a higher COMP voltage level, and it is easy to touch the trip point. The compensa-

tion components also affect the response of COMP voltage; smaller caps may give a faster response.

The output current has faster rising time during short;the COMP pin will have a sharp rise. However,

if the cur-rent rises too fast, it may cause a false trip. The output capacitance and its ESR can affect

the rising time of the current during short.

八,相关产品 更多同类产品......

|

Switching Regulator > Buck Controller |

||||||||||

|

Part_No |

Package |

Archi tectu |

Phase |

No.of PWM Output |

Output Current (A) |

Input Voltage (V) |

Reference Voltage (V) |

Bias Voltage (V) |

Quiescent Current (uA) |

|

|

min |

max |

|||||||||

|

SOP-14 QSOP-16 QFN4x4-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

8000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP8|TSSOP8 |

VM |

1 |

1 |

5 |

5 |

13.2 |

1.25|0.8 |

5~12 |

3000 |

|

|

SOP-8 |

VM |

1 |

1 |

10 |

3.3 |

5.5 |

0.8 |

5 |

2100 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

2000 |

|

|

TSSOP-24 |QFN5x5-32 |

VM |

1 |

2 |

20 |

5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP14 QSOP16 QFN-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

4000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

25 |

2.2 |

13.2 |

0.8 |

12 |

5000 |

|

|

LQFP7x7 48 TQFN7x7-48 |

VM |

1 |

6 |

0.015 |

1.4 |

6.5 |

- |

5 |

1800 |

|

|

TSSOP-24P |

VM |

1 |

2 |

20 |

2.97 |

5.5 |

0.8 |

5~12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

3000 |

|

|

SOP-8-P|DIP-8 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

1.2 |

12 |

3000 |

|

|

SSOP28 QFN4x4-24 |

VM |

1 |

2 |

20 |

5 |

24 |

0.9 |

5 |

1200 |

|

|

SOP-20 |

VM |

1 |

2 |

20 |

2.2 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8|DFN3x3-10 |

VM |

1 |

2 |

- |

- |

- |

- |

5~12 |

550 |

|

|

DIP8|SOP-8 |

VM |

1 |

1 |

1 |

1.2 |

9 |

24 |

5 |

9 ~ 24 |

|

|

SSOP16 QFN4x4-16 TQFN3x3-16 |

VM |

1 |

1 |

25 |

3 |

25 |

0.6 |

5 |

1700 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

3 |

25 |

0.5 |

5 |

350 |

|

|

QFN4x4-24 |

CM |

2 |

1 |

40 |

4.5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8P TDFN3x3-10 |

VM |

1 |

1 |

20 |

3 |

13.2 |

0.8 |

5~12 |

2500 |

|

|

SOP8P |

VM |

1 |

1 |

25 |

3 |

13.2 |

0.6|0.8 |

5~12 |

1200 |

|

|

TDFN3x3-10 |

VM |

1 |

1 |

25 |

4 |

13.2 |

0.8 |

5~12 |

2000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

4.5 |

25 |

0.6 |

5~12 |

80 |

|

|

SOP-8P |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.8 |

5~12 |

16000 |

|

|

TQFN3x3-10 |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.6 |

5~12 |

2500 |

|

|

CXSD62101|L |

TDFN3x3-10 |

COT |

1 |

1 |

30 |

3 |

25 |

0.8 |

5~12 |

2000 |

|

TQFN3x3-16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

|

CXSD62102A |

TQFN 3x3 16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

QFN4x4-24 |

VM |

2 |

1 |

50 |

4.5 |

13.2 |

0.6 |

5~12 |

5000 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

CXSD62106|A |

TQFN4x4-4 TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

800 |

|

TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3.5x3.5-14 TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

TQFN3x3-16 |

COT |

1 |

2 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3x3-20 TQFN3x3-16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5|0.5 |

5 |

740 |

|

|

TQFN4x4-24 |QFN3x3-20 |

CM |

1 |

2 |

15 |

5 |

28 |

0.5 |

N |

3000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.5 |

5 |

250 |

|

|

CXSD62113|C |

TQFN3x3-20 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

CXSD62113E |

TQFN 3x3 20 |

COT |

2 |

2 |

11 |

6 |

25 |

2 |

N |

550 |

|

TQFN3x3-20 |

COT |

2 |

2 |

11 |

5.5 |

25 |

2 |

N |

280 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.85 |

12 |

5000 |

|

|

CXSD62116A|B|C |

SOP-8P |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

16000 |

|

SOP-20 |

VM |

2 |

2 |

30 |

10 |

13.2 |

1 |

12 |

5000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

1.8 |

28 |

0.7 |

5 |

250 |

|

|

TQFN3x3-20 |

COT |

2 |

1 |

40 |

1.8 |

25 |

REFIN Setting |

5 |

700 |

|

|

QFN 3x3 20 TQFN 3x3 16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5 1.35|1.2 0.5 |

5 |

800 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

180 |

|

◀ 上一篇:CXSD6288双通道恒定时间和同步的PWM控制器每个通道驱动双N通道MOSFET功率因数调制或脉宽调制模式下瞬态响应和精确的直流电压输出

下一篇▶:CXSD6290全桥配置中驱动两个高侧P通道和两个低侧N通道mosfet输出由PWM1和PWM2输入独立控制